联系人:何小姐

电 话:0769-89786428

传 真:0769-89026428

邮 编:430000

邮 箱:ruicailed@126.com

地 址:东莞市长安镇上沙北横街10号五楼

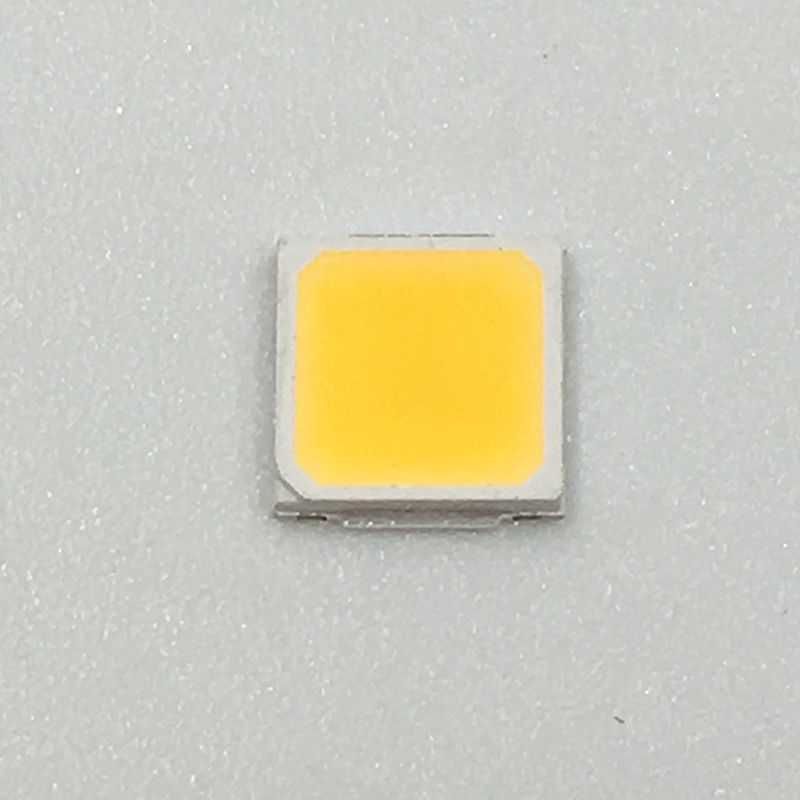

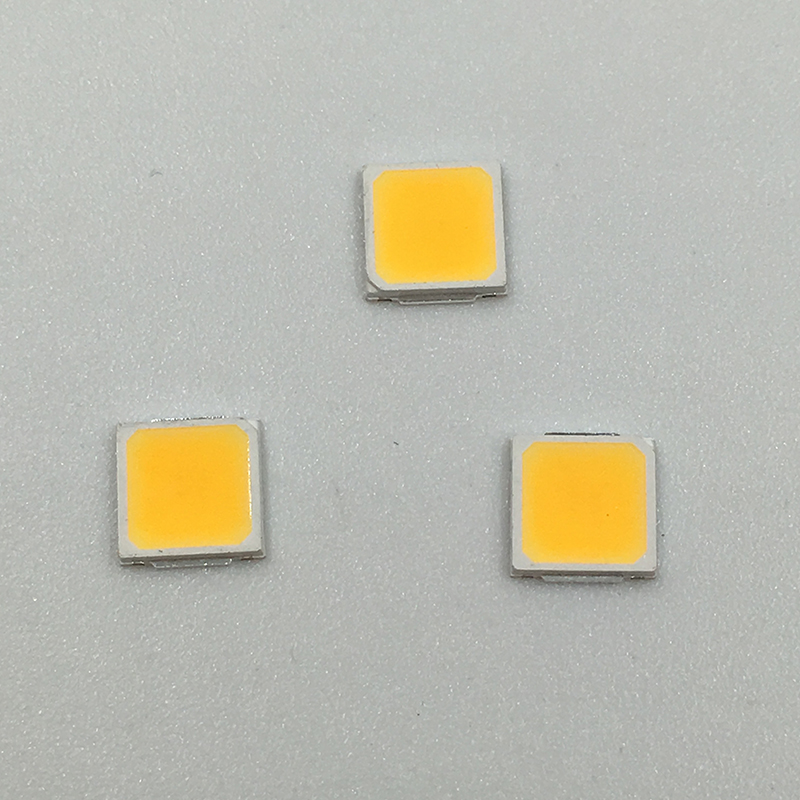

3030贴片灯珠

- 产品编号:

- 生产厂家:东莞市瑞彩电子信息科技有限公司

- 参考价格:面议

- 市场价格:面议

- 是否定制:

- 更新日期:2017/11/23 20:05:49

Product Brief (产品简介)

| Features and Benefits (特性优点) | Key Applications (应用) |

| Thermally Enhanced EMC Package Design.( 高耐热EMC封装) Mid Power to High Power, up to 1.3W(中功率,最大使用功率 1.3W) Max. Driving Current 200mA(最大操作电流200mA) High Color Quality with CRI Min. 80(显指Ra≥80) Pb-free Reflow Soldering Application(适用无铅回流焊) | Retrofits(replacement)(传统照明替换) General lighting(普通照明) Indoor & Outdoor sign board back light(背光) Architectural / Decorative lighting(景观装饰照明) |

Table 1. Product Selection Table

| Model No. 型号 | Color 颜色 | Min. 最小值 | CCT 色温 Typ. 典型值 | Max. 最大值 |

| T3C65821A-**A | Cool White | 6020K | 6530K | 7040K |

| T3C57821A-**A | Cool White | 5310K | 5665K | 6020K |

| T3C50821A-**A | Neutral White | 4745K | 5028K | 5311K |

| T3C40821A-**A | Neutral White | 3710K | 3985K | 4260K |

| T3C30821A-**A | Warm White | 2870K | 3045K | 3220K |

| T3C27821A-**A | Warm White | 2580K | 2725K | 2870K |

Performance Characteristics (特性参数)

Table 2. Electro Optical Characteristics (光电特性), IF = 150mA , Ta = 25℃, RH60%

| Color Bin 色区 | Color Rendering 显指 | Luminous Flux 光通量 | |

| Min 最小值 | Typ 典型值 | Min 最小值 | |

| 27M5 | 80 | 125 | 114 |

| 30M5 | 80 | 131 | 122 |

| 40M5 | 80 | 135 | 122 |

| 50M5 | 80 | 135 | 122 |

| 57M6 | 80 | 135 | 122 |

| 65M6 | 80 | 135 | 122 |

Tolerance of measurements of the Luminous Flux is ±7%(LM测试误差±7%)

Ra measurement tolerance is ±2(Ra测试误差±2)

Correlated Color Temperature is derived from the CIE 1931 Chromaticity diagram (CCT参考CIE 1931色度图)

The lumen table is only for reference(LM参数供参考)

Ta = 25℃, RH60% (温度:25 ℃,湿度:60%)

Table 3. Electro Optical Characteristics (光电特性), IF = 150mA , Ta = 25℃, RH60%

| 項目 Item | 符號 Symbol | 測試條件 Test condition | Value 数值 | 單位 Unit | ||

| 最小值 Min | 典型值 Type | 最大值 Max | ||||

| 正向電壓 Forward voltage | VF | IF=150mA | - | 6.1 | 6.6 | V |

| 反向電流 Reverse current | IR | VR=5V | - | - | 10 | μA |

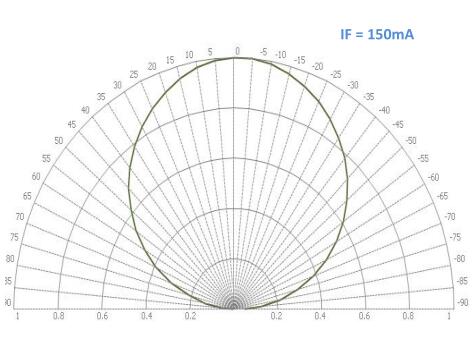

| Viewing Angle 发光角度 | 2θ1/2 | IF = 150mA | - | 120 | - | |

| Thermal Resistance 热阻 | (Rth j-sp ) | IF = 150mA | - | 13 | - | ℃/W |

| Electrostatic Discharge 抗静电 | ESD | HMB | 1000 | - | - | V |

Tolerance : VF :±0.1V(VF测试误差±0.1V)

2Θ1/2 is the off-axis where the luminous intensity is 1/2 of the peak intensity(2Θ1/2即为发光强度为峰值强度1/2的角度)

Thermal resistance : RthJS (Junction / solder) 热阻值 (结点至焊点)

Ta = 25℃, RH60% (温度:25 ℃,湿度:60%)

Table 4. Absolute Maximum Ratings (最大额定参数), Ta = 25 ℃, RH60%

| Item 参数名称 | Symbol 符号 | Absolute Maximum Ratings 最大额定参数 | Unit 单位 |

| Forward Current 正向电流 | IF | 200 | mA |

| Pulse Forward Current 正向脉冲电流 | IFP | 300 | mA |

| Power Dissipation 功率损耗 | PD | 1320 | mW |

| Reverse Voltage 反向电压 | VR | 5 | V |

| Operating Temperature 操作温度 | Topr | -40~+105 | ℃ |

| Storage Temperature 储存温度 | Tstg | -40~+105 | ℃ |

| Junction Temperature 结温 | Tj | 125 | ℃ |

| Soldering Temperature 回流温度 | Tsld | 230℃or 260℃for 10sec | |

IFP condition with Pulse: Width≤100μs Duty cycle≤1/10

LED’s properties might be different from suggested values like above and below tables if operation condition will be exceeded our

parameter range. Care is to be taken that power dissipation does not exceed the absolute maximum rating of the product

正向脉冲电流条件:脉冲宽度≤100μs,占空比≤1/10

操作条件若超出最大额定参数,可能会对LED造成不可预期伤害

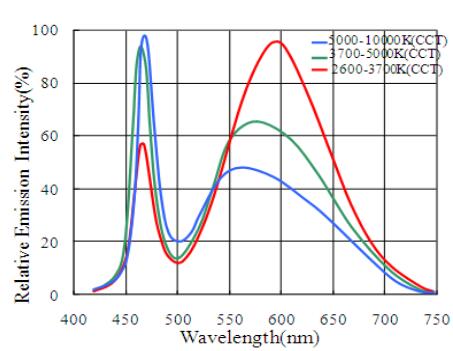

| Fig 1. Color Spectrum (光谱图), Ta = 25℃, RH60% | Fig 2. Viewing Angle Distribution (发光角度), Ta = 25℃, RH60% IF = 150mA |

|  |

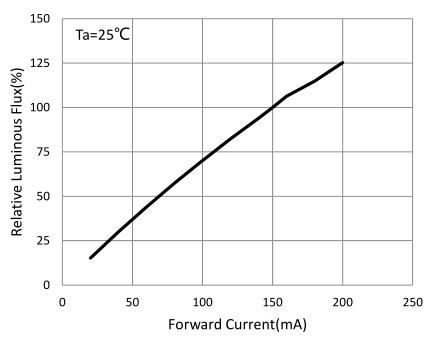

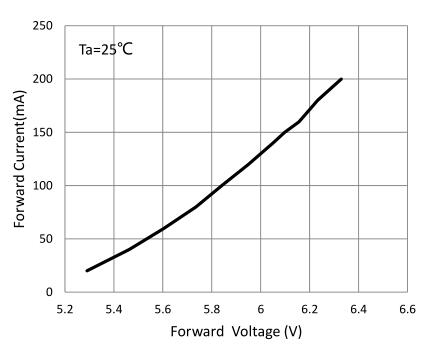

| Fig 3. IF vs. Relative Luminous flux, , , Ta = 25℃ (亮度与电流关系,温度=25 ℃ ) | Fig 4. Forward Voltage vs. Forward Current , Ta = 25℃ (电压与电流关系,温度=25℃ ) |

|  |

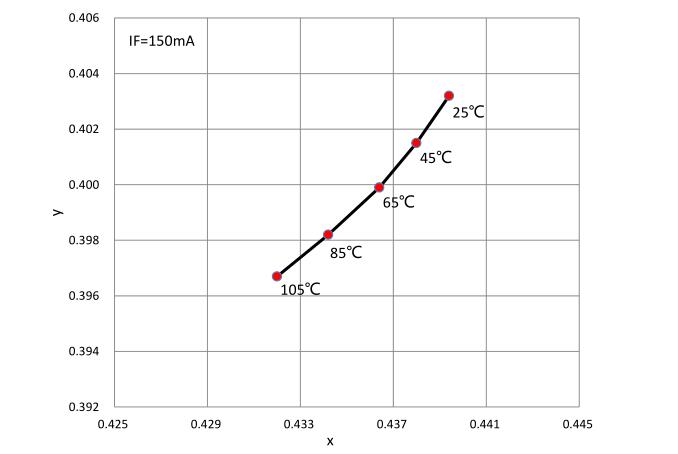

Fig 5. Ts vs. CIE x, y Shift (温度与CIE x, y关系)

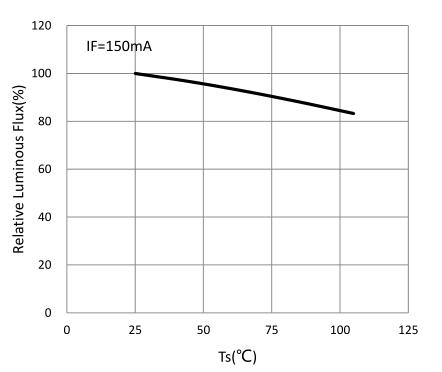

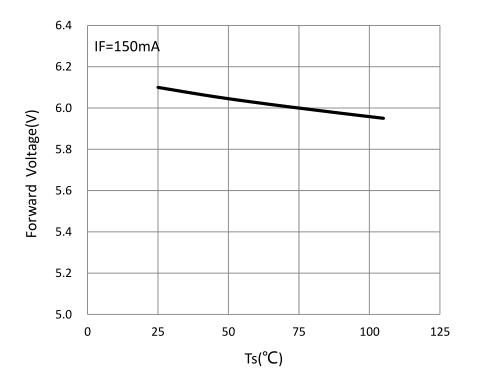

| Fig 6. Ts—Relative Luminous flux (温度与亮度关系) | Fig 7. Ts—Forward Voltage (温度与电压关系) |

|  |

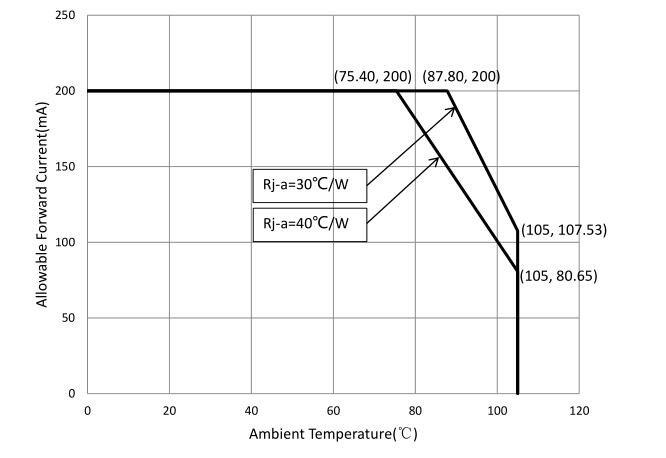

Fig 8, Maximum Forward Current vs. Ambient Temperature (最大正向电流 vs 温度)

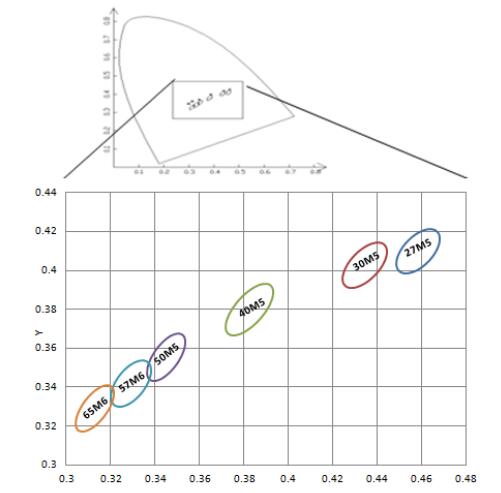

Fig 9, CIE Chromaticity Diagram (CIE 色区图), IF = 150mA, Ta = 25℃

All measurements were made under the standardized environment of Lightning LED.

所有测量都在天电标准环境下进行

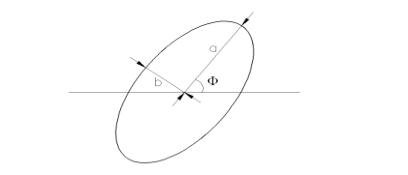

Table 5. Bin Code description (分光色区图), IF = 150mA , Ta = 25℃, RH60%

| Color Code 色区代码 | Center 色区中心点 | Radius 半径 | Angle 角度 | ||

| X | Y | A | B | Φ | |

| 27M5 | 0.4582 | 0.4099 | 0.013500 | 0.00700 | 53.42 |

| 30M5 | 0.4342 | 0.4028 | 0.013900 | 0.00680 | 53.13 |

| 40M5 | 0.3825 | 0.3798 | 0.015650 | 0.00670 | 53.43 |

| 50M5 | 0.3451 | 0.3554 | 0.013700 | 0.00590 | 59.37 |

| 57M6 | 0.3290 | 0.3417 | 0.013410 | 0.00660 | 58.35 |

| 65M6 | 0.3130 | 0.3290 | 0.013380 | 0.00570 | 58.34 |

Energy Star binning applied to all 2600~7000K(所有2600~7000K分色方式参照能源之星定义)

Measurement Uncertainty of the Color Coordinates : ± 0.007(色坐标的测试误差:±0.007)

Ta = 25℃, RH60% (温度:25 ℃,湿度:60%)

Table 6. Luminous Flux Ranks (光通量分档), IF = 150mA , Ta = 25℃, RH60%

| Color Code 色区代码 | Color Rendering 显指 | Luminous Flux 光通量 | |||

| Min 最小值 | Typ 典型值 | Code 代码 | Min 最小值 | Max 最大值 | |

| 27M5 | 80 | 82 | 2D | 114 | 122 |

| 2E | 122 | 130 | |||

| 2F | 130 | 139 | |||

| 30M5 | 80 | 82 | 2E | 122 | 130 |

| 2F | 130 | 139 | |||

| 2G | 139 | 148 | |||

| 40M5 | 80 | 82 | 2E | 122 | 130 |

| 2F | 130 | 139 | |||

| 2G | 139 | 148 | |||

| 50M5 | 80 | 82 | 2E | 122 | 130 |

| 2F | 130 | 139 | |||

| 2G | 139 | 148 | |||

| 57M6 | 80 | 82 | 2E | 122 | 130 |

| 2F | 130 | 139 | |||

| 2G | 139 | 148 | |||

| 65M6 | 80 | 82 | 2E | 122 | 130 |

| 2F | 130 | 139 | |||

| 2G | 139 | 148 | |||

Tolerance of measurements of the Luminous Flux is ±7%(光通量的测量误差:±7%)

Ra measurement tolerance is ±2(Ra 测量误差:±2)

Correlated Color Temperature is derived from the CIE 1931 Chromaticity diagram(相关色温来源于CIE 1931色度图)

Ta = 25℃, RH60% (温度:25 ℃,湿度:60%)

Table 7. Forward Voltage Ranks (正向电压分档), IF = 150mA , Ta = 25℃, RH60%

| Code 代码 | Min 最小值 | Max 最大值 | Unit 单位 |

| C8 | 5.5 | 6.0 | V |

| D8 | 6.0 | 6.5 | V |

| E8 | 6.5 | 7.0 | V |

| Code 代码 | Min 最小值 | Max 最大值 | Unit 单位 |

| A4 | 5.8 | 6.0 | V |

| B4 | 6.0 | 6.2 | V |

| C4 | 6.2 | 6.4 | V |

| D4 | 6.4 | 6.6 | V |

Tolerance of measurements of the Forward Voltage is ±0.1V (正向电压的测量误差:±0.1V)

Ta = 25℃, RH60% (温度:25 ℃,湿度:60%)

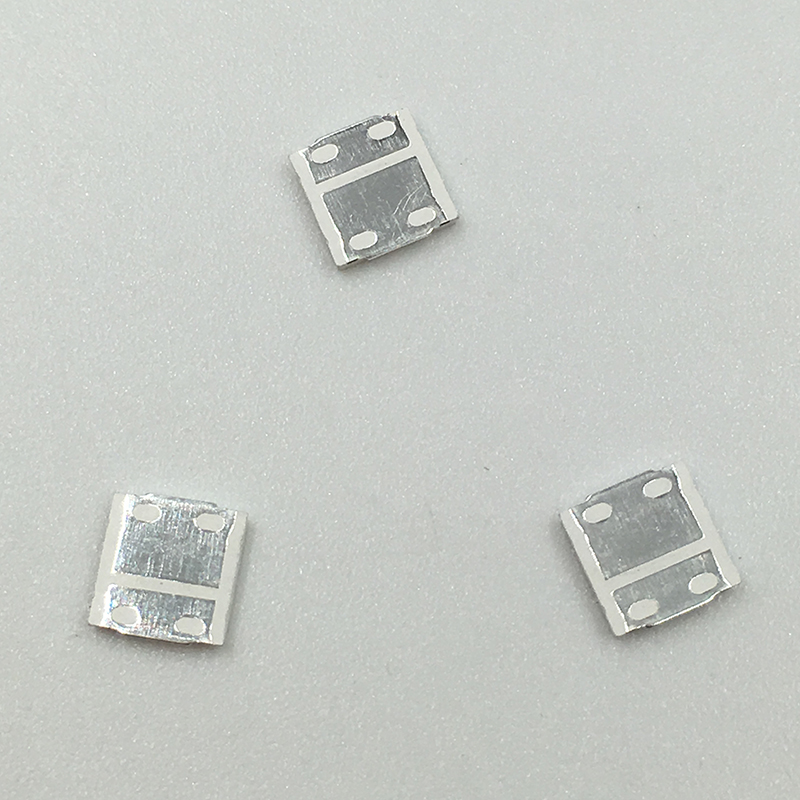

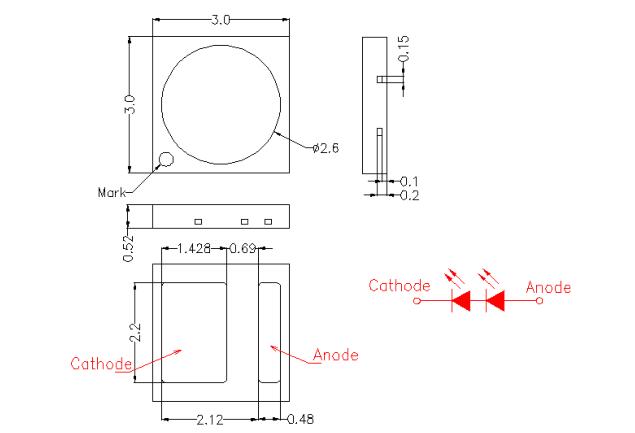

Mechanical Dimensions (产品尺寸)

All dimensions are in millimeters(图中所有尺寸均以毫米为单位)

Scale : 1:1 (比例:1:1)

Undefined tolerance is ±0.2mm(尺寸公差:±0.2毫米)

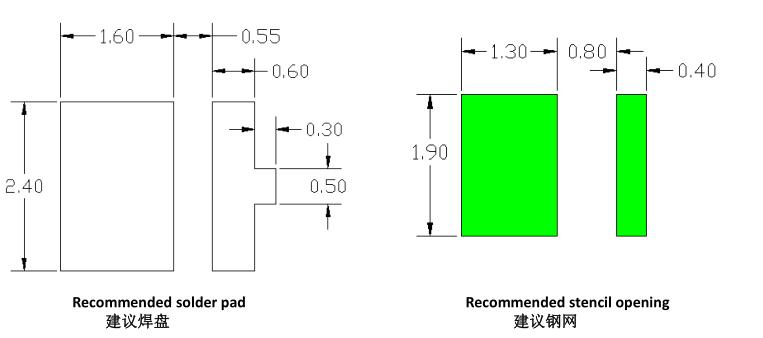

Recommended Solder Pad (焊盘设计)

All dimensions are in millimeters

Scale : 1:1

This drawing without tolerances are for reference only

Undefined tolerance: ±0.10mm

图中所有尺寸均以毫米为单位

比例:1:1

图纸仅供参考

若无特殊标注,图中公差尺寸为±0.10mm

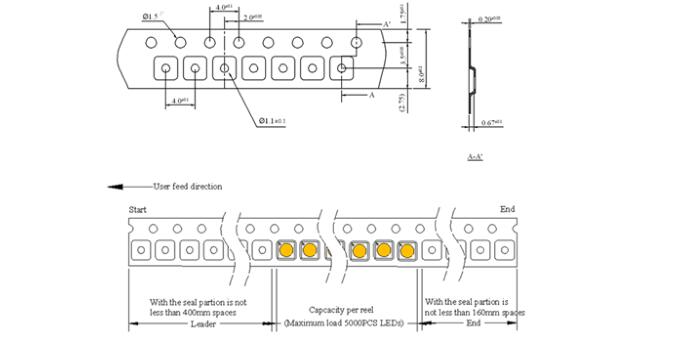

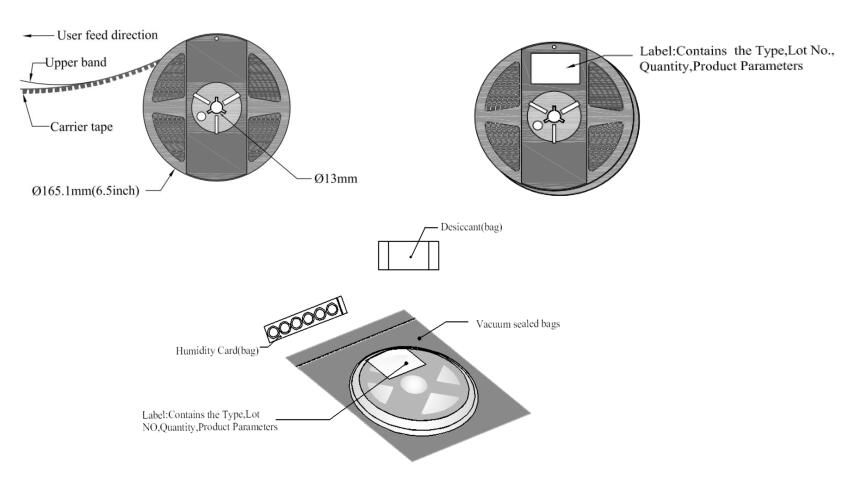

Packaging Information (包装信息)

Reel Packaging (卷带包装)

Quantity : Max 5000pcs/Reel

Cumulative Tolerance : Cumulative Tolerance/10 pitches to be ±0.2mm

Adhesion Strength of Cover Tape Adhesion strength to be 0.1-0.7N when the cover tape is turned off from the carrier tape at the angle of 10°to the carrier tape.

Package : P/N, Manufacturing data Code No. and Quantity to be indicated on a damp proof Package.

数量: 最多5000pcs/卷

10 pitches累积公差 :±0.2mm

上带剥离强度为0.1-0.7N(上带与载带成10°角剥离)

包装信息包含料号, 生产日期及数量等

Reel Packaging (卷带包装)

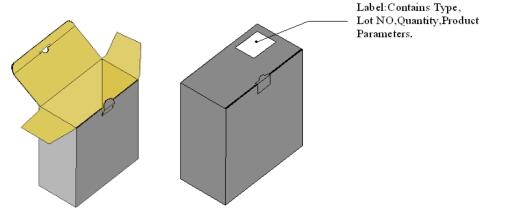

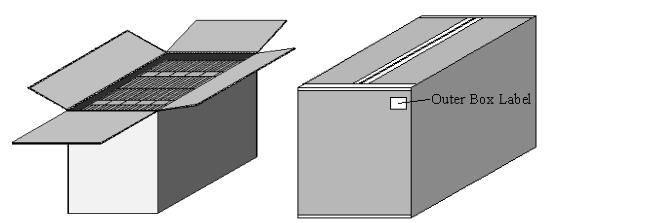

Inner Box (内箱)

Capacity 5 or 10 reels per box(内箱容量:5或10卷)

Outer Box (外箱)

Capacity 30 or 60 reels per box(外箱容量:30或60卷)

Table 8. Part Numbering System (命名原则)

| Item Number Code 序号代码 | Description 描述 | Content 内容 |

| X1 | Type code 产品代码 | 1S:1010; 1A:1919; 20:2016; 3B:3014; 34:3020; 3C:3030; 5C:5050; 7C:7070; 1D:100100; 19:Ceramic 3535; 15:Ceramic 5050; 11:Ceramic 1616. |

| X2 | CCT code 色温代码 | 2700K:27; 3000K:30; 4000K:40; 5000K:50; 5700K:57; 6500K:65. |

| X3 | Color Rendering 显指 | Ra70:7; Ra80:8; Ra90;9. |

| X4 | No. of serial chip 晶片串联数量 | 1-Z. |

| X5 | No. of parallel chip 晶片并联数量 | 1-Z. |

| X6 | Component code 补充码 | A-Z. |

| X7 | Color Code 分光标准 | M:ANSI; F:ERP; R:85℃ ANSI; T:105℃ ANSI; B:Backlighting; Q:Others |

| X8 | Chip Code 芯片代码 | \ |

| X9 | Internal code1 内部代码 | \ |

| X10 | Spare code 备用码 | \ |

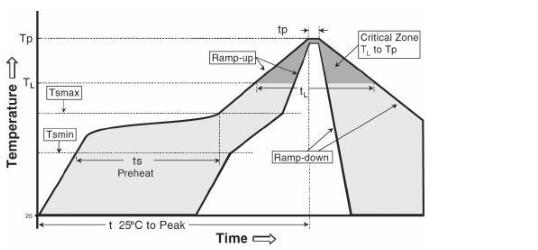

Reflow Soldering Characteristics (建议回流焊方式)

| Reflow soldering | |

| Temperature Min (Tsmin) Temperature Max (Tsmax) Time(ts)from ( Tsmin to Tsmax) | 150°C 200°C 60-120 seconds. |

| Ramp-up rate (TL to Tp) | 3°C/seconds max. |

| Liquidous temperature( TL) Time(tL) maintained above TL | 217°C 60-150 seconds |

| Peak package body temperature( Tp) | 260°C max |

| Time (tp) within 5°C of the specified classification temperature(Tc). | 30 seconds max |

| Ramp-down rate (Tp to TL) | 6°C/second max |

| Time 25°C to peak temperature | 8 min max |

Pre-caution for use (注意事项)

Caution

1. Reflow soldering is recommended not to be done more than two times. In the case of more than 24 hours passed

soldering after first, LEDs will be damaged.

2. Repairs should not be done after the LEDs have been soldered. When repair is unavoidable, suitable tools must be

used.

3. Die slug is to be soldered.

4. When soldering, do not put stress on the LEDs during heating.

5. After soldering, do not warp the circuit board.

Notes on Lightning EMC Series soldering:

1. Recommend to use reflow machine.

2. Recommend to use heating plate soldering.

3. Manual soldering is not recommended.

Notes on reflow process:

1. To confirm whether the actual temperature curve in the reflow soldering conditions comply with recommended

conditions. LEDs are guaranteed for one time reflow.

2. During reflow process do not apply force on LED active area.

3. After reflow process, PCB board should be cooled down before packing or storage.

注意:

1. 回流焊建议不要超过两次。

2. LED焊接后不建议重工,当重工不可避免时,必须使用合适的工具。

3. 不可虚焊。

4. 焊接加热过程中,请勿施加压力于LED表面 。

5. 焊接后,请勿弯曲电路板。

焊接注意事项:

1. 建议使用回流焊机器。

2. 建议使用加热板焊接。

3. 不建议手动焊接。

回流焊注意事项:

1. 确保实际温度曲线与回流焊接条件相符合。

2. 在回流过程中,请勿施加压力于LED表面 。

3. 回流后,PCB板在包装或存储前需冷却至常温。

上一篇:没有了!

下一篇:没有了!